Under construction - check back regularly as our site is updated! (7/8/2019)

LIBERTY GRAIN RESCUE TUBE

The Liberty Grain Rescue Tube was the first commercially available system designed specifically to aid in the extrication of partial grain entrapment victims. Introduced in 2005, the Liberty Rescue Tube was developed by farm safety and grain handling professionals. The device was designed based on research into successful grain entrapment rescue situations, and the input and experiences of first responders.

The 4-paneled Liberty Grain Rescue Tube can be used to create a coffer dam around an entrapment victim, allowing grain to be vacuumed or removed by hand from around the victim. Prior to the introduction of the Liberty Rescue Tube, first responders had to rely on whatever materials happened to be on-site (plywood, etc.) to create a coffer dam. The Liberty Rescue Tube offers rescue personnel a self-contained, easily transported , and purpose-built system that is highly adaptable to a variety of grain storage and handling situations.

Safety of first responders is of utmost importance in any rescue scenario. Users of the Liberty Grain Rescue Tube must be properly trained in implementing the system, as well as the many potential hazards associated with grain rescue situations!

Features

Lightweight & easy assembly

- Each panel weighs less than 15 pounds

- Non-conductive ultra-high-molecular-weight (UHMW) polyethylene panels

- Panels interlock with no protruding components (handles, locking mechanisms) to increase friction resistance

- No straps, bolts, or latches required for assembly

- Flexibility for greater access into confined spaces

All-weather use with any type of grain or condition

- High impact resistance, even in cold weather

- Compatible for use with all common grain products, along with most feed

- Low surface friction in both wet and dry grain

- Slide hammer (included) allows tube to be driven into crusted grain

Comprehensive User's Manual

- Developed by safety, first response, and grain industry professionals

- Detailed instructions and supporting information

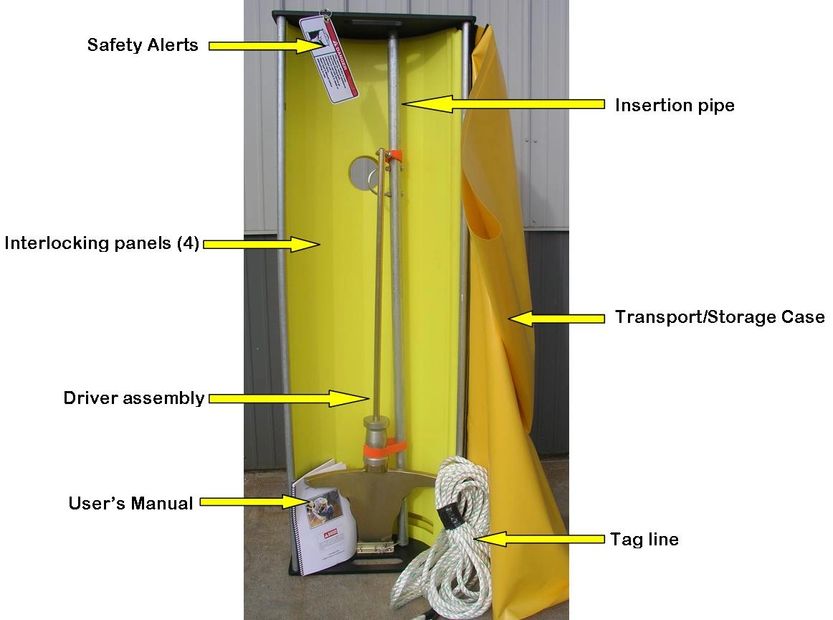

System Components

Why UHMW Polyethlene?

During the original design and testing of the LIBERTY GRAIN RESCUE TUBE®, a variety

of materials were considered, including; PVC, stainless steel, aluminum, and recycled

polyethylene. Each had undesirable qualities such as excessive weight, high surface friction or

low impact or deformation strength. The solution arrived at was ultra-high-molecular-weight

polyethylene or UHMW polyethylene. This form of thermoplastic polyethylene is chemically

comprised of long molecular chains with a high molecular weight resulting in a very tough

material. It has the highest impact strength of any thermoplastic presently available. In addition,

it has extremely low moisture absorption, will not rust, has very low surface coefficient of

friction, highly resistant to abrasion and compatible to the temperature extremes found in typical

grain handling situations. It is used widely in extremely tough applications such as skis,

snowboards, linings of material handling equipment, bearings, knee replacements, and

components on agricultural equipment. It would be harder to find a more suitable material for

fabrication of a grain rescue device.

Liberty Rescue Systems

1105 North 1025 East, Lafayette, Indiana 47905, United States

Copyright © 2019 Liberty Rescue Systems - All Rights Reserved.